Application of Impact Crushers in Road Construction Materials: Building a Solid Foundation

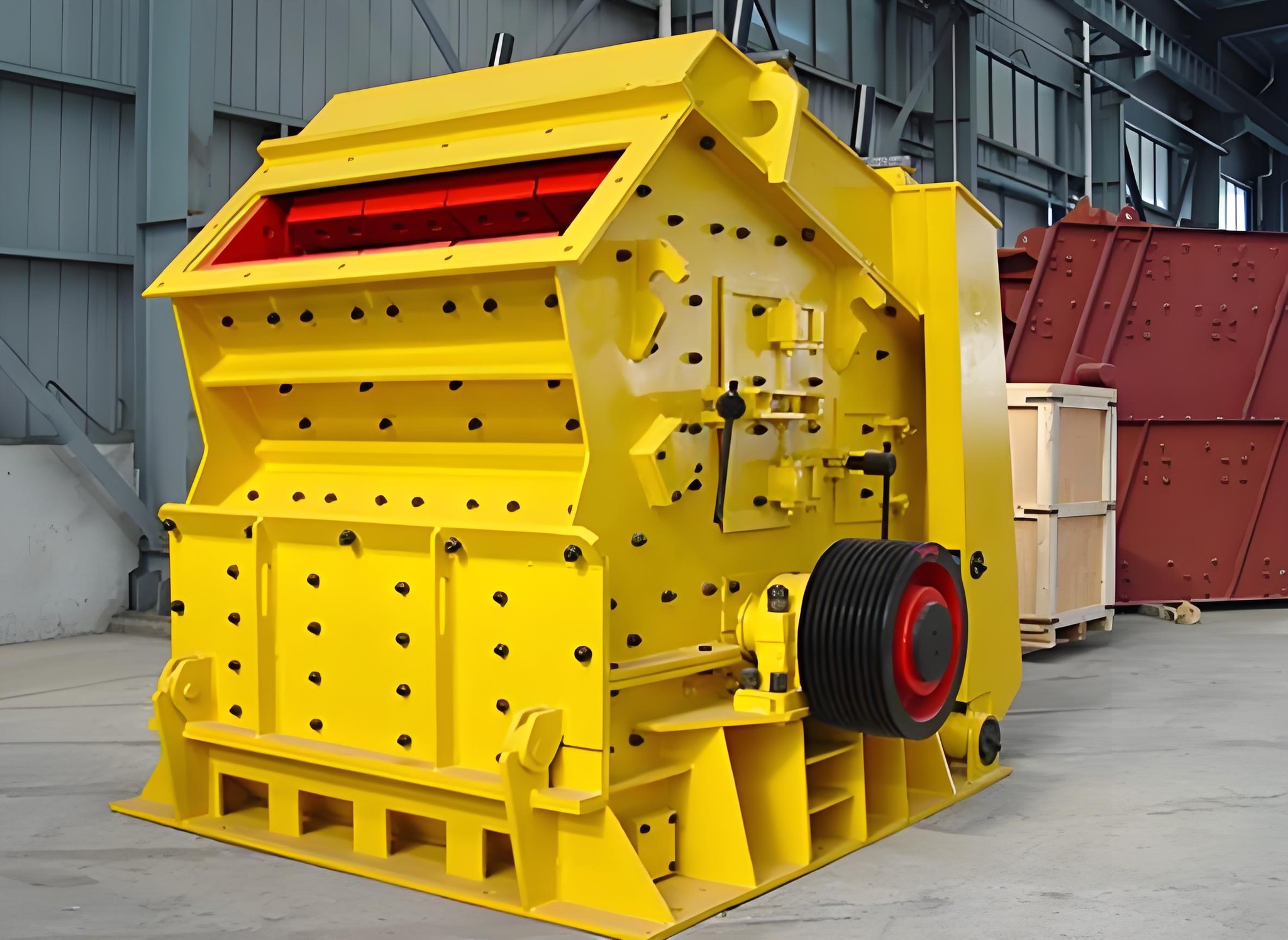

Road construction demands aggregates that are not only strong and durable but also possess specific gradation and shape characteristics to ensure long-term stability and performance. Impact crushers (also known as horizontal shaft impactors) have emerged as a pivotal technology in producing the high-quality crushed stone essential for various layers of road infrastructure, from the base to the surface. This article explores the critical role of impact crushers in meeting the stringent requirements of road engineering materials.

I. Why Road Construction Favors Impact Crushers

The unique working principle of impact crushers—utilizing high-speed rotors and hammers to shatter rock through impact—makes them exceptionally suited for road material production.

1. Production of Superior Cubical Aggregates:

- Impact crushing promotes inter-particle collision, resulting in a final product with a high percentage of cubical grains. This shape is paramount for road bases and asphalt mixtures as it ensures excellent interlock and compaction, reducing voids and enhancing load-bearing capacity.

- Improved particle shape directly contributes to better stability, resistance to rutting, and longer pavement life.

2. Precise Gradation Control for Specific Road Layers:

- Modern impact crushers allow for significant control over the output gradation through adjustable rotor speed, impact plate gap, and grinding path design.

- This enables producers to tailor crushed stone to exact specifications for different applications:

- Base & Sub-base Layers: Well-graded, angular aggregates (e.g., 0-40mm, 20-63mm) for maximum density and drainage.

- Asphalt Concrete (Surface Course): Consistently sized, cubical chips (e.g., 5-11mm, 11-16mm) for optimal binder adhesion and skid resistance.

3. High Efficiency in Processing Common Road Construction Materials:

- Impact crushers excel at processing medium-hard to hard rocks commonly used in road building, such as limestone, dolomite, and certain types of granite and basalt.

- They offer a high reduction ratio, often capable of producing finished or near-finished product sizes in a single crushing stage, streamlining the production circuit.

II. Key Advantages in Road Project Context

1. Operational Flexibility and Cost-Effectiveness:

- Impact crushers can be configured as primary or secondary crushers in a road material plant, offering layout flexibility. Their relatively simpler design can lead to lower initial investment and easier maintenance compared to cone crushers for certain materials.

- High throughput capacities support the large-scale material demands of major road projects.

2. Effective Recycling of Construction Demolition Waste (CDW):

- A crucial modern application is the processing of reclaimed asphalt pavement (RAP) and demolished concrete into high-quality recycled aggregates for road bases. Impact crushers are highly effective in liberating and sizing these materials, promoting sustainable construction practices.

3. Adaptability to Mobile Crushing Setups:

- Mobile impact crusher plants are invaluable for on-site crushing during road construction or rehabilitation projects. They eliminate the need for material transport from a stationary quarry to distant work sites, significantly reducing costs, traffic, and carbon footprint.

III. Typical Crushing Circuit for Road Materials

A standard setup often involves:

- Primary Jaw Crusher: Produces initial size reduction.

- Secondary/Tertiary Impact Crusher: Further crushes the material, optimizing shape and final sizing. A closed-circuit system with a screening unit is commonly used to recirculate oversize material, ensuring precise gradation control.

- Screening: Multiple decks of vibrating screens separate the crushed product into the specific fractions required for different road layers.

IV. Conclusion: The Strategic Choice for Durable Roads

For contractors, government agencies, and aggregate producers focused on road construction, the impact crusher is more than just a piece of crushing equipment—it is a strategic tool for quality assurance and efficiency.

By delivering aggregates with the optimal combination of strength, gradation, and most importantly, cubical shape, impact crushers directly contribute to building road foundations that are more stable, surfaces that are more durable, and ultimately, infrastructure that is safer and requires less maintenance over its lifecycle.

When the project’s success depends on the quality of the granular layers, specifying materials produced by a well-configured impact crushing system is a decision grounded in both engineering principles and economic sense.

- > Basalt Rock Crushers in New Zealand: A Vital Tool for Construction and Mining

- > Impact Crusher Working Principle: A Simple Guide to How It Works

- > The Application of Jaw Crushers in Gold Mining Operations

- > What Materials Are Suitable for a Small Hammer Crusher?

- > HSPF Series Impact Crushers for Ore Crushing

- > Application of Cone Crusher in Secondary and Tertiary Crushing in Metal Ore Beneficiation Process

- > Impact Crushers for Gold Mining in the Middle East

- > Mobile Dolomite Cone Crushers: Revolutionizing Mining Operations in Nigeria

Online

Message