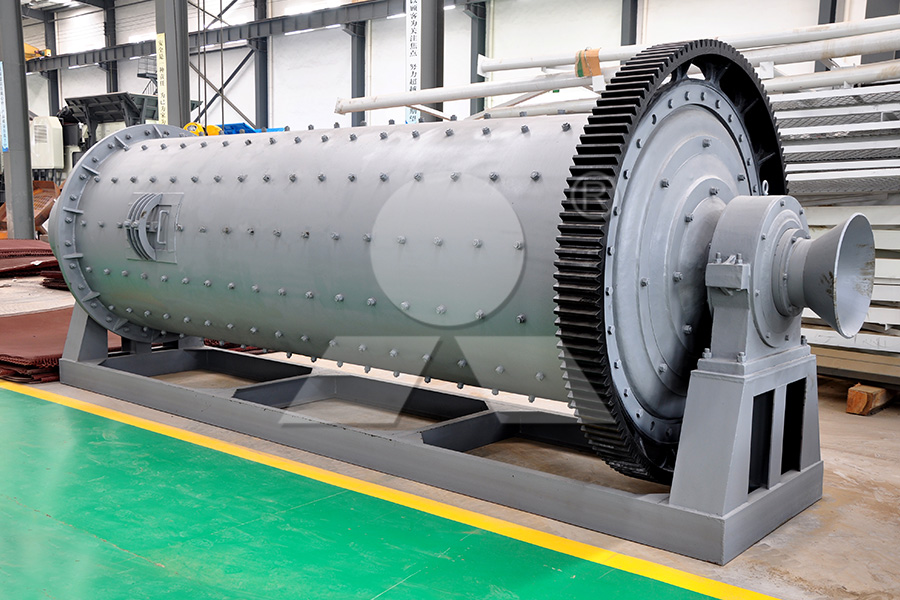

Optimized Ball Mill with a 50-Ton per Hour Capacity for Enhanced Ore Processing

A ball mill with a capacity of 50 tons per hour is a highly efficient piece of equipment used in mineral processing, particularly in industries dealing with materials such as ore, cement, and various raw materials. This milling capacity provides substantial throughput while maintaining the quality of grinding and achieving desired particle size, making it ideal for large-scale operations in mining, construction, and other related sectors.

Key Benefits of a 50-Ton per Hour Ball Mill

- High-Volume Output

This type of ball mill is specifically designed to handle high volumes of raw materials, grinding them down with precision. The 50-ton-per-hour capacity enables facilities to process vast quantities of materials quickly, which can significantly streamline production timelines and meet large-scale demand. - Efficient Grinding and Consistency

The milling process within this equipment ensures a consistent grind, producing fine particles suited for further processing or direct use. The precision with which a 50-ton-per-hour ball mill operates reduces the need for repeated milling stages, saving both energy and operational costs. - Versatility Across Applications

A 50-ton-per-hour ball mill is suitable for diverse applications, including mineral processing, cement production, and chemical processing. Its flexibility allows it to work with different material types and hardness levels, making it versatile equipment for various industrial needs.

Operational Advantages

- Enhanced Energy Efficiency

Modern ball mills of this capacity are often equipped with energy-saving technologies. The ability to process large quantities of material at once reduces power consumption per ton of output, leading to lower energy costs and improved sustainability. - Reduced Maintenance Downtime

With reinforced internal linings and high-quality components, these ball mills offer a long service life and minimal maintenance interruptions. The reliability of the equipment minimizes operational downtime, thus enhancing overall productivity. - Ease of Integration

Ball mills with a 50-ton-per-hour capacity are often designed for seamless integration into existing production lines. This feature simplifies setup and allows for quick adaptation, reducing initial implementation costs and making it an accessible option for facilities seeking to expand their capacity.

Applications in Industrial Sectors

- Mining Industry

In mining, a high-capacity ball mill is crucial for the efficient processing of ore. It allows for the rapid grinding of ores like copper, gold, and iron, preparing them for further extraction or refinement stages. The high throughput rate of a 50-ton-per-hour mill makes it particularly valuable in high-demand scenarios. - Cement Production

Cement manufacturing requires consistent particle size, which a 50-ton-per-hour ball mill can achieve. The mill is ideal for blending raw materials like limestone and clay, creating the fine powders required for quality cement production.

Cost-Effectiveness and Return on Investment

Investing in a ball mill with a 50-ton-per-hour capacity yields excellent returns by improving processing times, reducing energy costs, and supporting higher production outputs. Facilities can quickly recover their investment due to the increased operational efficiency and the mill’s ability to handle demanding workloads without sacrificing quality.

Conclusion

A ball mill with a 50-ton-per-hour capacity offers substantial advantages in industries requiring high throughput and consistent grinding quality. With operational benefits such as energy efficiency, ease of integration, and versatility, it is a highly valuable asset in mineral processing and production facilities. This high-capacity mill not only meets large-scale demands but also enhances productivity and cost-efficiency in the long term.

- > Advantages and Disadvantages of Cone Crushers: A Comprehensive Overview

- > How to Reduce Jaw Plate Wear in Jaw Crushers: Causes and Solutions

- > The Versatility of Cone Crushers: Material Processing Range and Applications

- > Impact Crusher for Granite Processing

- > Vibrating Jaw Crusher: A Powerful Solution for Russia’s Mining Industry

- > Application of Vibrating Screens in Civil Construction

- > Advantages of Using Cone Crushers in Pakistan’s Mining Industry

- > Rock Impact Crusher: An Essential Tool for Mining and Quarrying Operations

Hot Product

Online

Message