Application of Cone Crushers in Secondary Crushing for Mining

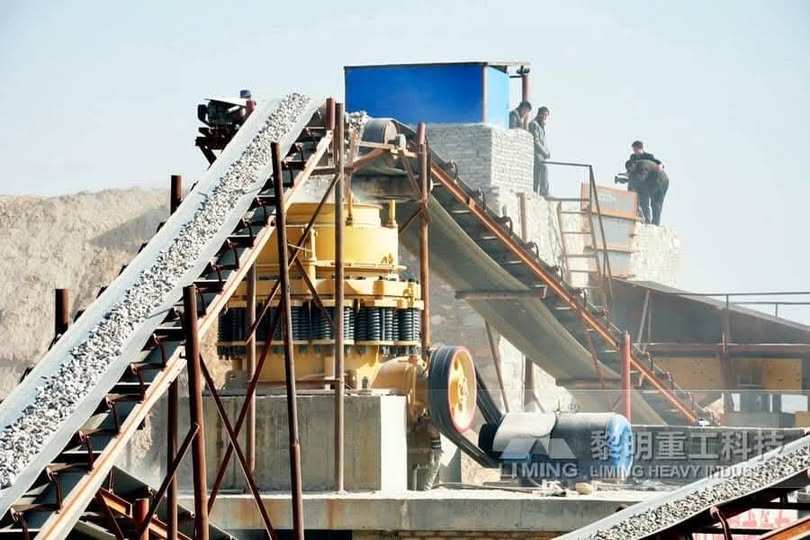

In the mining industry, secondary crushing plays a crucial role in reducing raw materials to the desired size for further processing. Cone crushers are widely used in this stage due to their high efficiency, excellent particle shape, and durability. These crushers are ideal for handling medium to hard rock materials, making them essential in mining operations.

This article explores the application of cone crushers in secondary crushing, highlighting their advantages and key functions in mining operations.

1. Why Cone Crushers Are Ideal for Secondary Crushing

Cone crushers are specifically designed to handle materials that have already been processed in primary crushing (typically by jaw crushers). Their key advantages include:

✔ High reduction ratio – Efficiently reduces material size for further processing.

✔ Superior particle shape – Produces well-shaped aggregates suitable for various applications.

✔ Continuous and stable operation – Ensures consistent production with minimal downtime.

✔ Adjustable settings – Allows for flexibility in output size according to project requirements.

2. How Cone Crushers Work in Secondary Crushing

The working principle of a cone crusher involves:

🔹 Feeding process – Crushed material from the primary crusher enters the cone crusher’s chamber.

🔹 Compression and crushing – A rotating mantle compresses the material against the concave surface, breaking it down further.

🔹 Discharge of final product – The processed material exits through an adjustable opening, ensuring uniform particle size.

This crushing method ensures efficient size reduction, making cone crushers a vital part of modern mining operations.

3. Advantages of Cone Crushers in Mining

✅ High Efficiency – Provides continuous crushing with minimal energy consumption.

✅ Low Wear and Tear – Durable design with high-strength materials reduces maintenance costs.

✅ Adaptability to Different Materials – Suitable for crushing granite, basalt, iron ore, and other hard materials.

✅ Automation and Control – Many modern cone crushers come with automated control systems for optimized performance.

4. Key Applications in Mining

🔸 Processing hard and abrasive rocks – Ideal for reducing iron ore, copper ore, and other hard minerals.

🔸 Aggregates production – Used in quarrying operations for producing high-quality aggregates.

🔸 Gold and copper mining operations – Helps extract valuable minerals efficiently.

5. Conclusion

Cone crushers are a critical component in secondary crushing for mining operations. Their high efficiency, durability, and ability to handle hard materials make them indispensable in modern mining processes. By optimizing secondary crushing with advanced cone crusher technology, mining companies can enhance productivity and reduce operational costs.

Liming Heavy Industry specializes in high-performance cone crushers for mining applications. Contact us today for customized crushing solutions!

- > Comprehensive Guide to Installation and Commissioning of Mobile Crushing Stations

- > Performance of Mobile Crushing Stations in African Mining Operations

- > Application of Jaw Crushers in Magnetite Ore Beneficiation Processing

- > Rock Impact Crusher: An Essential Tool for Mining and Quarrying Operations

- > Key Process Points for Crushing Volcanic Rock in Indonesia with Jaw Crushers

- > When is a Mobile Crushing Plant the Right Choice? Ideal Working Conditions Explained

- > The Role of Impact Crushers in Iron Ore Mining

- > Can a Mobile Impact Crusher Produce Final Specification Aggregates On-Site?

Online

Message