Cone Crushers in Ghana’s Granite Quarrying: Enhancing Efficiency and Productivity

Ghana’s granite quarrying industry plays a significant role in the country’s construction sector, providing essential materials for building infrastructure. Among the various types of crushers used in the quarrying process, cone crushers stand out for their efficiency and ability to handle the hard granite stone that is prevalent in Ghana. This article explores the application of cone crushers in Ghana’s granite quarries, highlighting their benefits, operational principles, and how they enhance productivity.

1. The Role of Cone Crushers in Granite Quarrying

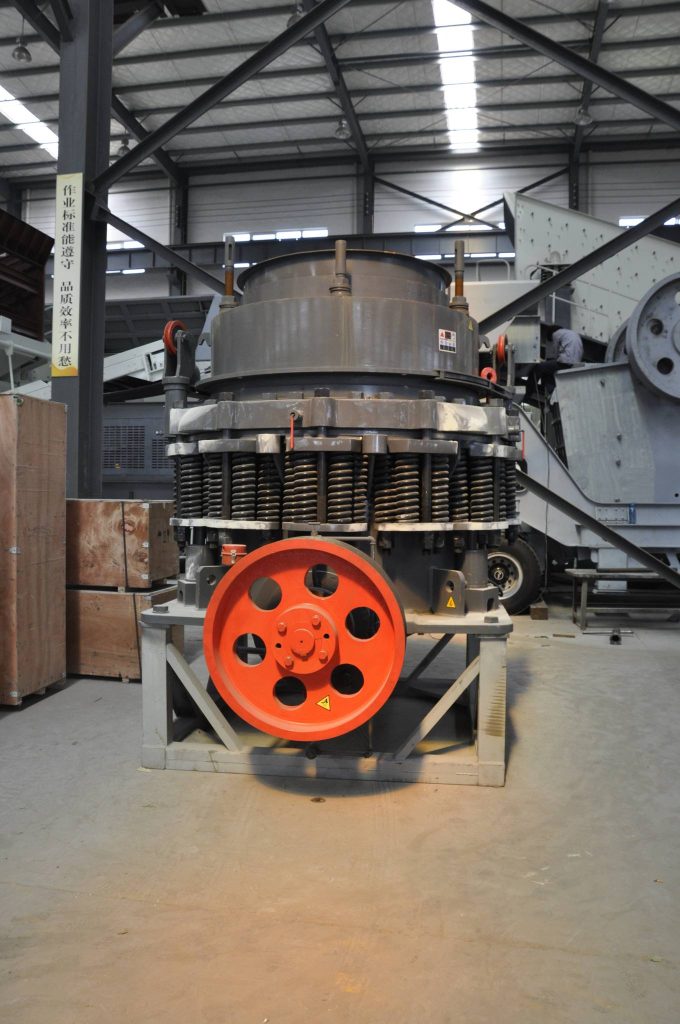

Granite is a hard and durable rock that is widely used in construction, especially for roads, buildings, and other infrastructure. To break down granite into smaller, usable sizes, cone crushers are employed. These machines are specifically designed to crush hard and abrasive materials like granite, making them an ideal choice for quarry operations in Ghana.

Cone crushers work by compressing the material between a moving cone and a stationary bowl. The force exerted by the moving cone fractures the granite, reducing it to smaller, more manageable sizes that can be further processed or used in construction.

2. Advantages of Cone Crushers for Granite

Cone crushers offer several advantages in the granite quarrying process:

- High Efficiency: Cone crushers are known for their high crushing efficiency, as they can handle large quantities of material in a relatively short amount of time. This ensures that production levels in the quarry remain high, meeting the growing demand for granite.

- Consistent Output: The design of cone crushers allows for precise control over the final product size. This consistency is critical in granite quarrying, where specific sizes are needed for different construction applications.

- Low Operational Costs: Compared to other crushers, cone crushers are more energy-efficient and require less maintenance, reducing operational costs in the long run. The durability of the parts used in cone crushers also means fewer replacements are needed, leading to lower downtime.

3. Durability and Reliability in Harsh Conditions

Granite quarrying in Ghana often takes place in harsh environments, where machinery is exposed to dust, moisture, and high levels of wear and tear. Cone crushers are built to withstand these conditions. The robust design and heavy-duty materials used in their construction ensure that they can operate effectively in even the most challenging environments.

Additionally, cone crushers are equipped with advanced technology that helps prevent damage from overloading or uncrushable materials. This feature extends the lifespan of the machine and minimizes disruptions in production.

4. Environmental Impact and Sustainability

With the growing emphasis on sustainable mining practices, cone crushers also offer benefits in terms of environmental impact. Their energy-efficient operation helps reduce carbon emissions, while the precision of the crushing process minimizes waste, ensuring that more of the granite is utilized.

By maximizing output and reducing energy consumption, cone crushers contribute to a more sustainable quarrying operation, which is becoming increasingly important in Ghana’s evolving mining sector.

5. Conclusion

In conclusion, cone crushers are an essential component in Ghana’s granite quarrying industry, providing the efficiency, reliability, and cost-effectiveness needed to process this hard material. With their high performance, durability, and ability to produce consistent output, cone crushers help optimize production in granite quarries, ensuring that Ghana continues to meet its construction demands. As quarry operators look for ways to improve their processes and reduce environmental impact, cone crushers will remain a crucial tool in the extraction and processing of granite.

- > Colombian-Made Mobile Impact Crusher

- > Mobile Impact Crushers in Argentina: A Key Solution for Efficient Material Processing

- > Advantages of Mobile Jaw Crusher in Construction Waste Recycling

- > Common Issues When Operating a Ball Mill in Stone Quarrying

- > Kenya’s Mobile Crusher Market: Trends, Drivers, and Opportunities

- > Mobile Cone Crushers: A Versatile Solution for Calcite Production

- > The Application of Cone Crushers in Mining

- > How to Reduce Jaw Plate Wear in Jaw Crushers: Causes and Solutions

Hot Product

Online

Message