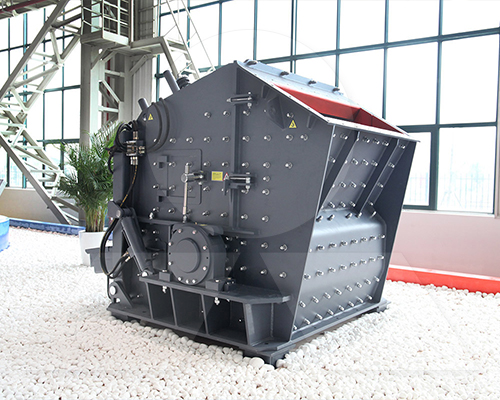

Highly Recommended Impact Crusher for Stone Crushing

The impact crusher is increasingly recognized as one of the most efficient and reliable machines for stone crushing in various industries. Whether used in mining, construction, or road building, this machine offers a high level of performance, efficiency, and adaptability, making it a top recommendation for any operation requiring high-quality stone crushing.

1. Superior Crushing Efficiency

One of the main reasons to highly recommend the impact crusher for stone crushing is its exceptional efficiency. Unlike traditional crushers, the impact crusher uses a unique crushing mechanism that allows it to break down materials faster and more efficiently. The rotor’s rapid spinning and the strategic placement of impact plates enable the machine to crush large stones into fine, uniform particles in a short period, significantly improving production rates.

2. Versatility Across Various Materials

The impact crusher stands out due to its adaptability. It is not limited to just crushing stones; it can process a wide range of materials, including limestone, granite, basalt, and even materials with higher hardness levels. This versatility is particularly valuable in industries where different types of rocks and minerals are processed, ensuring that the same machine can handle multiple crushing needs without requiring additional equipment.

3. Adjustable Output Size for Custom Needs

Another key advantage of the impact crusher is its adjustable output size. Operators can easily modify the settings to produce crushed stones of different sizes, depending on the specific project requirements. This flexibility makes it an excellent choice for diverse applications, such as producing gravel for roads, concrete aggregates, or fine materials for construction. The ability to fine-tune the output helps companies meet precise product specifications without needing multiple crushers.

4. Low Maintenance and Long Lifespan

The impact crusher is designed with durability in mind. Built using high-quality materials and advanced technology, this machine is able to withstand harsh operating conditions and continuous use. Key components, such as the blow bars and impact plates, are made from wear-resistant materials, reducing the need for frequent replacements and minimizing downtime. Additionally, the crusher’s design allows for easy access to parts, simplifying routine maintenance tasks and further extending the machine’s lifespan.

5. Cost-Effectiveness

When it comes to cost, the impact crusher proves to be a cost-effective option for stone crushing. Its high efficiency reduces operational costs by minimizing fuel and energy consumption, while the machine’s durability and low maintenance needs help cut down on repair expenses. This combination of factors ensures a high return on investment, making the impact crusher a financially sound choice for businesses seeking to maximize productivity while controlling costs.

6. Environmental Benefits

Modern impact crushers are designed with environmental concerns in mind. The machine’s ability to crush materials efficiently reduces the need for additional processing steps, leading to lower emissions and energy use. Furthermore, impact crushers often produce less dust compared to traditional crushers, contributing to a cleaner and safer work environment. This environmentally friendly aspect makes it an attractive choice for companies looking to meet regulatory requirements and reduce their environmental footprint.

Conclusion

In conclusion, the impact crusher is highly recommended for stone crushing due to its efficiency, versatility, and long-term cost-effectiveness. Its ability to handle various materials, deliver consistent results, and require minimal maintenance makes it a valuable asset for any stone crushing operation. Whether for large-scale mining or smaller construction projects, the impact crusher delivers the performance needed to meet demanding requirements, making it an essential tool for modern industries.

- > Key Process Points for Crushing Volcanic Rock in Indonesia with Jaw Crushers

- > Vibrating Screens for Crushed Stone and Gravel Processing: Equipment for Crushing and Screening Aggregates

- > Cone Crusher for High-Hardness Ores: Efficient Crushing Solutions

- > Impact Crushers for Gold Mining in the Middle East

- > Mobile Impact Crushers for Coal Processing in India

- > Key Reasons Behind Low Output in Jaw Crushers and How to Address Them

- > How to Adjust Jaw Crusher Discharge Size to 0-50mm

- > Application of Impact Crushers in Secondary Crushing and Shaping in Construction Aggregate Production Lines

Hot Product

Online

Message