Impact Crushers for Kaolin Processing in South Africa: An Overview

Kaolin, a type of clay mineral, is extensively utilized in various industries such as ceramics, paper, rubber, and paint due to its excellent properties. In South Africa, the processing of kaolin is critical, and impact crushers have proven to be highly effective in this process. This article explores the application and advantages of using impact crushers in kaolin processing in South Africa.

Importance of Kaolin in South Africa

South Africa is rich in kaolin deposits, which are essential for numerous industrial applications. The country’s mining sector plays a significant role in the extraction and processing of kaolin, providing raw materials for both domestic use and export. Efficient processing methods are crucial to maintaining the quality and competitiveness of South African kaolin in the global market.

Role of Impact Crushers in Kaolin Processing

Impact crushers are widely used in the mining and mineral processing industries for crushing and pulverizing materials. Their application in kaolin processing offers several benefits:

- High Crushing Efficiency: Impact crushers are designed to crush materials with high efficiency, reducing large chunks of kaolin into smaller, more manageable sizes. This increases the overall efficiency of the processing plant.

- Particle Size Control: These crushers provide excellent control over the particle size of the crushed material. By adjusting the settings, operators can ensure that the kaolin particles meet specific size requirements, essential for various industrial applications.

- Reduction of Over-Sized Particles: Impact crushers effectively reduce oversized particles, which is critical in maintaining the consistency and quality of the final product. This ensures that the kaolin meets industry standards.

- Versatility: Impact crushers are versatile machines capable of handling a variety of materials. In kaolin processing, they can be used at different stages of production, from primary crushing to fine grinding.

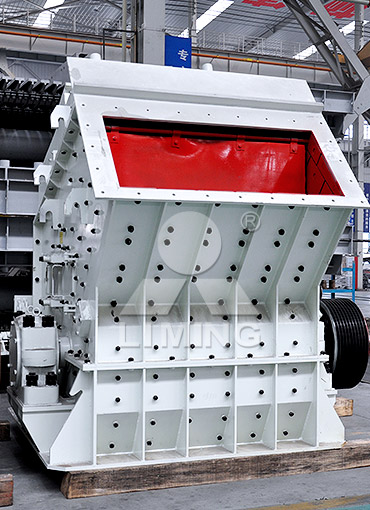

Features of Modern Impact Crushers

- Durable Construction: Modern impact crushers are built with durable materials that can withstand the harsh conditions of the mining industry. This ensures a long service life and reduces downtime due to maintenance and repairs.

- Adjustable Settings: The adjustable settings of impact crushers allow for precise control over the final particle size. This is particularly important in kaolin processing, where different applications require specific particle sizes.

- High Throughput Capacity: These crushers offer high throughput capacity, making them suitable for large-scale kaolin processing operations. This enhances the productivity of the processing plant and meets the demand for high volumes of kaolin.

- Energy Efficiency: Modern impact crushers are designed to be energy-efficient, reducing the overall energy consumption of the processing plant. This is an important factor in minimizing operational costs and environmental impact.

Application in South Africa

In South Africa, the application of impact crushers in kaolin processing has shown significant improvements in production efficiency and product quality. Several kaolin processing plants have integrated impact crushers into their production lines, benefiting from their advanced features and capabilities.

- Primary Crushing: Impact crushers are used in the primary crushing stage to break down large kaolin rocks into smaller pieces, facilitating easier handling and further processing.

- Secondary and Tertiary Crushing: In secondary and tertiary crushing stages, impact crushers further reduce the particle size, ensuring that the kaolin meets the required specifications for various industrial applications.

- Fine Grinding: For applications requiring very fine kaolin particles, impact crushers can be used in conjunction with other grinding equipment to achieve the desired particle size.

Conclusion

The use of impact crushers in kaolin processing in South Africa has proven to be highly effective, offering numerous advantages such as high crushing efficiency, particle size control, and versatility. These crushers are essential in ensuring the quality and competitiveness of South African kaolin in the global market. By integrating modern impact crushers into their processing operations, South African kaolin producers can enhance productivity, reduce operational costs, and maintain high standards of product quality.

- > The Application of Cone Crushers in Iron Ore Crushing

- > Efficiency and Applications of Small Rock Bauxite Jaw Crushers in Indonesia

- > Mobile Cone Crusher for Mining: The Ultimate Solution for Efficient Ore Crushing

- > Impact Crusher for Granite: The Best Solution for High-Efficiency Crushing

- > The Role of Vibrating Screens in the Mining Industry

- > Efficient Handling of Gravel and Crushed Stone: The Role of Cone Crushers

- > How Rock Hardness in Different Regions Impacts Crusher Selection

- > The Role of Cone Crushers in Iron Ore Beneficiation Processes

Hot Product

Online

Message