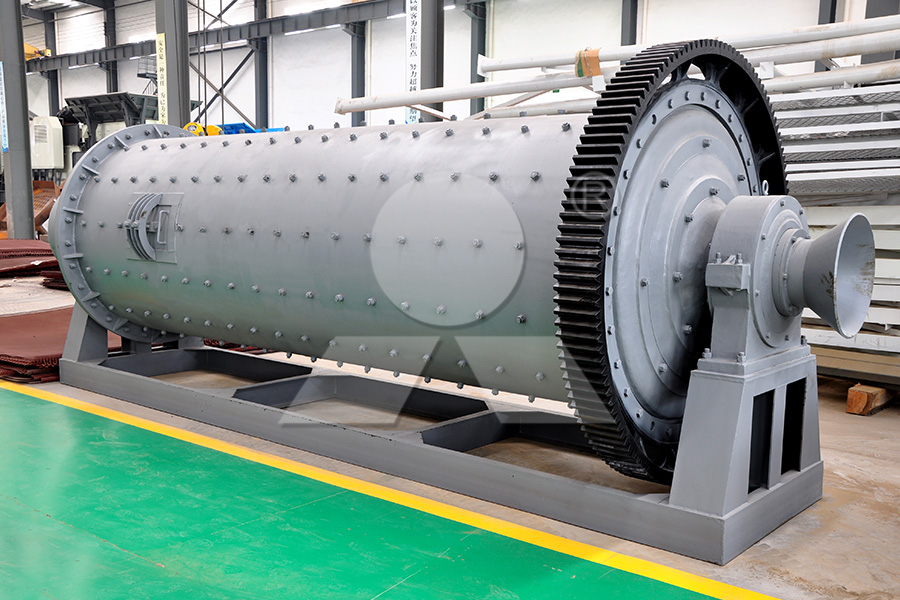

The Extensive Use of Popular Mining Ball Mills in Cement Production Lines

Mining ball mills have become an essential component in cement production lines worldwide, owing to their effectiveness in grinding raw materials and producing fine cement particles. As cement manufacturing continues to expand globally, ball mills remain one of the most popular and widely utilized pieces of equipment in the industry. In this article, we will explore the key role that mining ball mills play in the cement production process, their advantages, and why they are in such high demand.

The Role of Ball Mills in Cement Production

A ball mill is a cylindrical device that grinds materials like limestone, clinker, and gypsum into a fine powder, which is then used to produce cement. The grinding process occurs as the materials inside the rotating mill are crushed by steel balls, which move freely within the drum. This mechanical action reduces the particle size of the materials, making them suitable for further processing in the cement manufacturing cycle.

In cement production, ball mills are often used at two critical stages:

- Raw material grinding: Before raw materials can be heated in the kiln, they need to be finely ground to ensure a uniform mixture. Ball mills are ideal for this process due to their ability to handle various types of materials, from soft limestone to harder clinkers.

- Clinker grinding: After the clinker is produced in the kiln, it is ground with gypsum in the ball mill to create the final cement product. This step is crucial, as the quality of grinding directly affects the strength and quality of the cement.

Advantages of Using Mining Ball Mills in Cement Production

- Efficiency in grinding: Ball mills are highly efficient when it comes to grinding large volumes of material. The uniform particle size distribution they produce ensures that the cement meets the desired specifications, improving its strength and durability.

- Versatility: Mining ball mills are adaptable and can grind a wide range of materials used in cement production, from soft to extremely hard minerals. This versatility is key in a production line that needs to process different types of materials with varying hardness levels.

- Energy savings: Modern ball mills have been designed with energy efficiency in mind. New technologies in ball milling help reduce energy consumption during the grinding process, making them more environmentally friendly and cost-effective for cement producers.

- Scalability: Ball mills can be used in both small and large cement production lines. Their scalability allows them to be used by both small manufacturers and large industrial plants, making them a flexible solution for different production needs.

Why Ball Mills Are in High Demand in Cement Manufacturing

The consistent demand for cement in the construction industry fuels the need for high-performance equipment like mining ball mills. As construction projects increase, especially in developing countries, there is a greater need for reliable and durable machinery to keep up with production demands.

Additionally, the global push for sustainable practices in construction has prompted cement producers to focus on energy-efficient solutions. Ball mills, with their ability to reduce energy consumption and enhance productivity, have become a popular choice for many cement manufacturers looking to lower operational costs and meet environmental regulations.

Conclusion

Mining ball mills play a pivotal role in cement production lines, providing the grinding efficiency needed to produce high-quality cement. Their adaptability, energy efficiency, and scalability make them a top choice for manufacturers seeking to optimize their production processes. As cement demand continues to rise, the use of ball mills in the industry is expected to remain extensive, driving their popularity in global markets. With ongoing technological advancements, ball mills are poised to become even more efficient and environmentally friendly, ensuring their relevance in cement manufacturing for years to come.

- > Tire-Mounted Mobile Crushing Station: Which Terrains Are Suitable?

- > Portable Impact Crusher: A High-Performance Solution for Granite Processing

- > The Application of Jaw Crushers for Coal Crushing in Indonesia

- > Mobile Cone Crusher: Revolutionizing Construction Waste Recycling

- > Cone Crusher for High-Hardness Ores: Efficient Crushing Solutions

- > The Role of Jaw Crushers in the Cement Industry

- > Application of Mobile Crushing Plants in Road Widening Projects

- > Gravel Impact Crusher for Concrete Aggregates: Enhancing Construction Efficiency

Online

Message