The Operational Characteristics of Cone Crushers

Cone crushers play a pivotal role in the mining and construction industries, particularly in the processing of minerals and aggregates. Understanding their operational characteristics can provide valuable insights into their efficiency, durability, and versatility. This article delves into the key aspects of cone crusher operation, highlighting what makes them essential equipment in these industries.

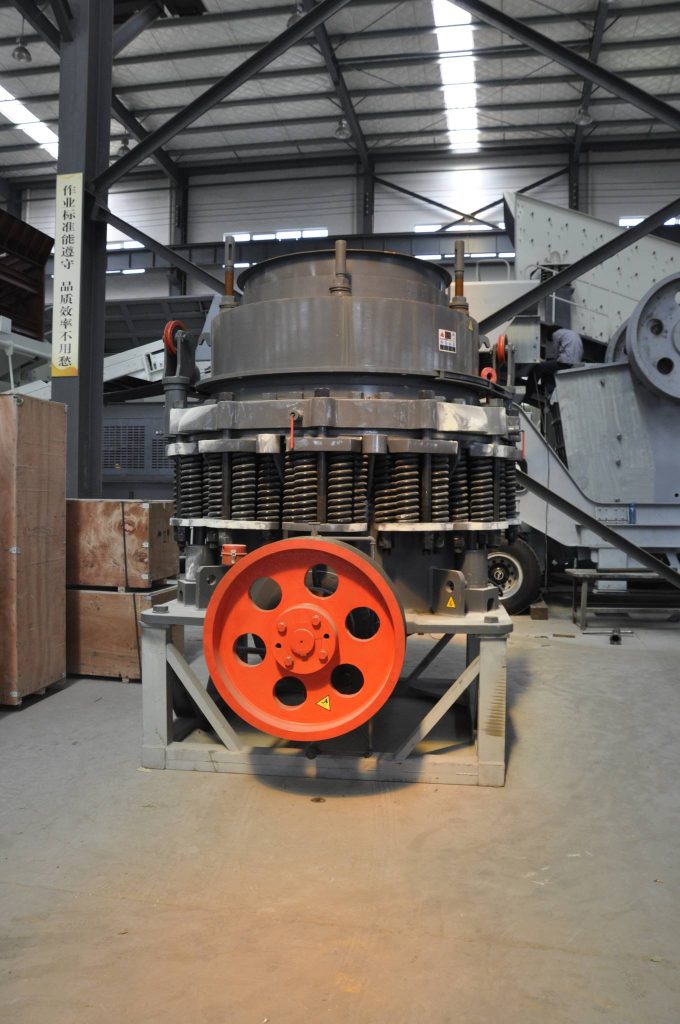

1. Crushing Mechanism and Design

Cone crushers operate based on a crushing mechanism that involves a conical head that gyrates within a stationary bowl. The material to be crushed is fed into the top of the crusher and is compressed between the moving head and the bowl, breaking it into smaller pieces. The design of cone crushers allows for a more consistent and uniform output size, which is crucial for producing high-quality aggregates.

2. High Efficiency and Low Operational Costs

One of the standout features of cone crushers is their high efficiency. The unique design and operational parameters allow these machines to process large volumes of material with minimal energy consumption. This efficiency translates to lower operational costs, making cone crushers a cost-effective solution for large-scale operations. Additionally, modern cone crushers are equipped with automated control systems that optimize performance and reduce downtime.

3. Versatility and Adaptability

Cone crushers are highly versatile machines capable of handling a variety of materials, from hard rock to softer minerals. Their adaptability is enhanced by the ability to adjust the crusher settings to achieve different output sizes and production requirements. This flexibility makes cone crushers suitable for a wide range of applications, including secondary, tertiary, and quaternary crushing stages.

4. Durability and Maintenance

The durability of cone crushers is another critical characteristic. These machines are built to withstand harsh working conditions and heavy loads. High-quality materials and robust construction ensure a long operational life. Furthermore, maintenance is relatively straightforward, with easy access to critical components and simplified replacement procedures. Regular maintenance checks and timely replacements of wear parts can significantly extend the lifespan of a cone crusher.

5. Advanced Technological Integration

Modern cone crushers incorporate advanced technologies that enhance their performance and reliability. Features such as hydraulic adjustment systems, real-time monitoring, and automation improve operational efficiency and safety. For instance, hydraulic systems allow for quick and precise adjustments to the crusher settings, reducing downtime and ensuring optimal performance. Real-time monitoring systems provide valuable data on the crusher’s operation, enabling predictive maintenance and reducing the risk of unexpected failures.

6. Environmental Considerations

In today’s environmentally conscious world, the operational characteristics of cone crushers also include considerations for sustainability. These machines are designed to minimize dust and noise emissions, making them more environmentally friendly. Efficient energy use and the ability to recycle materials further contribute to their eco-friendly credentials.

Conclusion

Cone crushers are indispensable in the mining and construction industries, offering a blend of efficiency, versatility, and durability. Their advanced technological features and low operational costs make them a preferred choice for many operations. Understanding their operational characteristics can help operators and engineers maximize their performance and extend their service life, ensuring they continue to play a crucial role in material processing for years to come.

- > The Application of Vertical Roller Crushers in the Cement Industry

- > Cone Crusher Applications in Pakistan’s Stone Quarrying Industry

- > Aplicación de Trituradoras Móviles para Basalto, Caliza y Cuarzo en la Industria de Agregados

- > Cone Crusher in Metal Ore Beneficiation Production Line

- > Performance of Mobile Crushing Stations in African Mining Operations

- > Selection and Maintenance Guidelines for Cone Crusher Lubricating Oil

- > Mobile Crushers for Dolomite Crushing

- > Jaw Crusher Performance in Volcanic Rock Processing: A Robust and Efficient Solution

Online

Message