The Role of Concrete Impact Crushers in Cement Production Lines

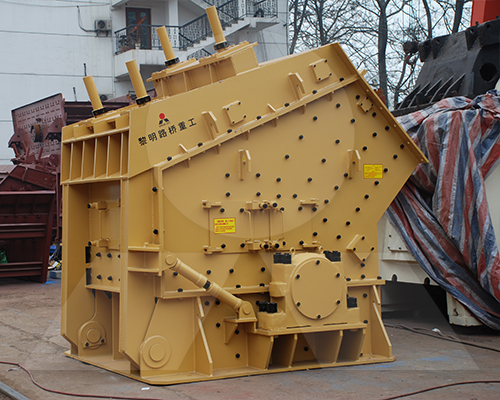

In the cement production process, concrete impact crushers play an essential role in achieving finely crushed material necessary for the formation of quality cement. These crushers are particularly useful in the processing of raw materials like limestone and other aggregates that need to be pulverized to specific particle sizes, ensuring an optimal mix for cement production.

Key Advantages of Using Impact Crushers in Cement Production

- High Crushing Efficiency: Impact crushers offer high efficiency in reducing large rocks and aggregates into finer particles, which is critical in cement production. The crushing process enables the raw materials to achieve an ideal consistency, which facilitates smooth mixing and curing in subsequent cement-forming stages.

- Uniform Particle Size: One of the main benefits of impact crushers is their ability to create a more uniform particle size. This consistency is crucial in cement manufacturing, where particle uniformity ensures that the cement paste hardens evenly, improving the overall quality and strength of the final product.

- Versatile and Adaptable Design: Impact crushers are available in various configurations to handle a range of materials and capacities. This versatility allows cement plants to adjust the equipment based on specific production requirements, leading to more efficient resource management and reduced operational costs.

Applications in Cement Production Lines

Concrete impact crushers are typically used at the initial stages of cement production, where raw materials such as limestone, clay, and shale are processed. By breaking down these materials into smaller, manageable sizes, impact crushers enable more efficient grinding and blending. The finely crushed particles ensure a homogeneous mix that is essential for producing high-quality cement.

These crushers are also employed in the secondary and tertiary stages of production to refine the particle size further, ensuring that the material meets the stringent standards needed for cement.

Maintenance and Efficiency Tips

To maintain peak efficiency, impact crushers in cement production lines should be routinely inspected and serviced. Regular checks on rotor components, wear-resistant plates, and lubrication levels help prolong the equipment’s life and prevent unexpected downtime. Additionally, monitoring the size and hardness of incoming materials can help prevent potential blockages and ensure smooth operations.

Conclusion

Concrete impact crushers are invaluable in cement production lines, offering the necessary strength and efficiency to process raw materials for high-quality cement. Their ability to create uniform particles, adaptability to different material types, and durability make them an ideal choice for cement plants aiming to optimize production. With proper maintenance and strategic use, these crushers enhance productivity and contribute significantly to the overall success of the cement manufacturing process.

- > Crushers in Gold and Platinum Mining: Streamlining the Extraction Process

- > Advantages of Portable Mobile Crushers in Construction Waste Recycling

- > The Role of Portable Jaw Crushers in California’s Construction and Mining Industries

- > Suitability of Mobile Crushing Plants in Mining Operations

- > Advantages of Using a 400×400 Roller-Type Stone Impact Crusher in Sand Production Lines

- > VSI Vertical Shaft Impact Crusher for Particle Shape Optimization in Concrete Aggregates

- > Crawler Mobile Cone Crusher for Fine Crushing in Gold Mining

- > Applications of Impact Crushers in the Construction and Mining Industries

Online

Message