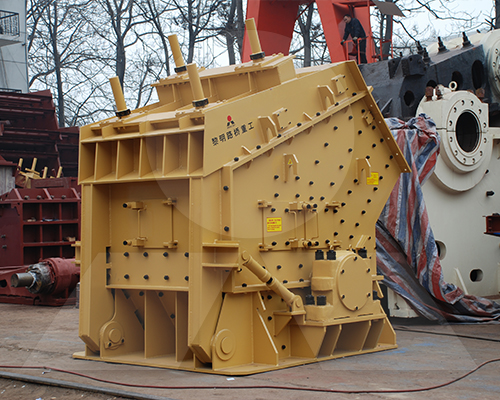

Copper Ore Impact Crusher: An Effective Tool for Secondary Processing in Ore Cleaning

In the mining industry, particularly in the extraction and processing of copper ore, the role of impact crushers is critical in the secondary processing stage. A copper ore impact crusher is specifically designed to handle the rigorous demands of crushing and refining copper ore, ensuring that the material is prepared effectively for subsequent processing steps.

1. Optimized Secondary Processing

The copper ore impact crusher plays a vital role in the secondary processing stage of ore cleaning. After the initial crushing process, where large chunks of copper ore are reduced in size, the impact crusher takes over to refine the material further. This secondary processing ensures that the ore is broken down into smaller, more manageable pieces, making it easier to extract pure copper in the later stages.

2. High Efficiency and Precision

Impact crushers are known for their efficiency and precision in the crushing process. When applied to copper ore, these crushers utilize their high-speed impact force to break down the ore, ensuring that each piece is crushed to the desired size. This level of precision is crucial in the mining industry, where the uniformity of the crushed material can significantly impact the quality and yield of the final product.

3. Cost-Effective Solution for Ore Cleaning

Utilizing a copper ore impact crusher for secondary processing offers a cost-effective solution for ore cleaning operations. The crusher’s ability to efficiently handle large volumes of ore reduces the need for multiple crushing stages, leading to lower operational costs. Additionally, the durability and reliability of the impact crusher minimize the need for frequent maintenance, further contributing to cost savings.

4. Improved Copper Recovery Rates

One of the significant advantages of using an impact crusher in copper ore processing is the improvement in copper recovery rates. By effectively breaking down the ore into smaller particles, the impact crusher exposes more surface area of the ore to the extraction process. This increased exposure allows for more efficient separation of copper from the ore, resulting in higher recovery rates and better overall yield.

5. Versatility in Processing

Copper ore impact crushers are versatile machines that can handle various types of ores and materials. In addition to copper ore, these crushers can be used for processing other minerals, making them a valuable asset in a mining operation. Their ability to adapt to different materials ensures that mining companies can use the same equipment across various projects, increasing operational flexibility.

6. Conclusion

The use of a copper ore impact crusher for secondary processing in ore cleaning is a strategic choice that enhances the efficiency, precision, and cost-effectiveness of mining operations. By ensuring that copper ore is thoroughly processed and ready for further refinement, these crushers play a crucial role in maximizing recovery rates and improving the overall productivity of mining operations. Investing in a reliable impact crusher is, therefore, essential for any mining operation focused on copper extraction and processing.

- > Portable Cone Crushers in Costa Rica: A Key to Efficient Crushing Solutions

- > Adaptability of Jaw Crushers to High-Moisture Content Materials

- > Advantages and Disadvantages of Using Vertical Impact Crushers for Nickel Ore Processing

- > Is the Small Jaw Crusher Ideal for Rural Road Construction? Applications and Benefits

- > Impact Crushers for Gold Mining in the Middle East

- > Applications of Impact Crushers in the Construction and Mining Industries

- > How Effective Are Mobile Impact Crushers for Crushing Concrete Blocks?

- > Jaw Crusher Solutions for the Crushing Challenge of High-Moisture Clay Ore in Indonesia

Hot Product

Online

Message