What Materials is an Impact Crusher Suitable For?

Selecting the right crusher is critical for the efficiency and cost-effectiveness of your operation. The impact crusher is a popular choice for many applications, but its performance heavily depends on the material being processed. So, what materials is an impact crusher best suited for? This article provides a clear guide to the ideal and unsuitable materials for impact crushing, helping you make an informed decision.

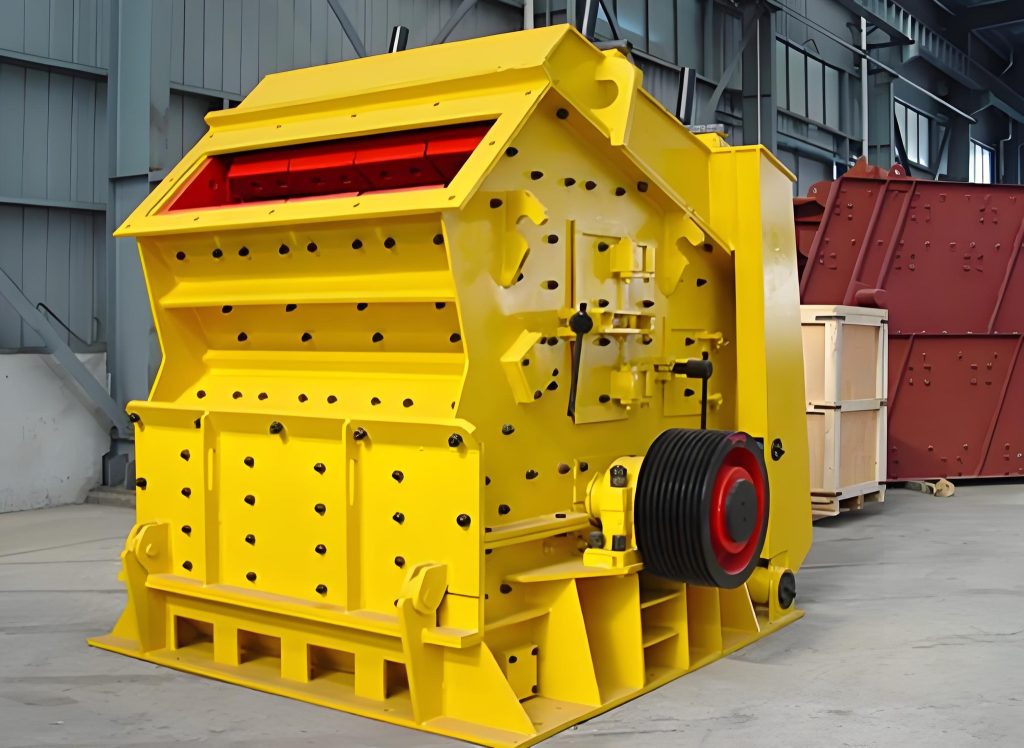

How an Impact Crusher Works: The Key to Material Suitability

To understand material suitability, it’s essential to know how an impact crusher works. It utilizes the principle of impact crushing where rocks are fed into a rapidly rotating rotor equipped with hammers (blow bars). The rotor throws the material against impact plates (apron liners), causing it to shatter along its natural fissures. This action results in a high reduction ratio and produces a uniformly cubic-shaped product.

Ideal Materials for an Impact Crusher

Impact crushers excel at processing medium-hard to hard materials that are non-abrasive. Their unique crushing mechanism makes them particularly suitable for materials where a consistent, well-shaped end product is desired.

1. Limestone and Other Medium-Hard, Non-Abrasive Rocks

This is the classic application for an impact crusher. Limestone is relatively soft and breaks easily upon impact, making it highly efficient to process. Other similar sedimentary rocks like dolomite and sandstone are also excellent choices. The impact crusher produces a high-quality, cubical aggregate perfect for concrete and asphalt production.

2. Recycled Construction and Demolition Waste

Impact crushers are the go-to machine for concrete recycling and asphalt recycling. They are highly effective at crushing these materials, easily separating rebar and other light steel reinforcements. The ability to produce a clean, well-graded product from waste makes them indispensable in the recycling industry.

3. Coal and Gypsum

Softer minerals like coal and gypsum are perfectly suited for impact crushing. The machine can efficiently reduce these materials to the required size for further processing or direct use with low energy consumption and minimal wear on the blow bars.

4. Materials Requiring a Cubic End Product

If your primary goal is to produce aggregate with an excellent cubic shape for high-quality concrete or asphalt, an impact crusher is often the best choice. The impact force naturally creates more equidimensional particles compared to compression-style crushers.

Materials Unsuitable for an Impact Crusher

Knowing what to avoid is just as important. Impact crushers are not recommended for:

- Very Hard and Highly Abrasive Materials: Rocks like granite, basalt, and quartzite cause rapid wear of the blow bars and impact plates, leading to excessive maintenance costs and downtime.

- Sticky or Clay-Based Materials: Moist, clay-rich materials can clog the crushing chamber, reducing efficiency and requiring frequent cleaning.

- High-Silica Content Materials: These are highly abrasive and will accelerate wear parts consumption.

Advantages of Using an Impact Crusher for Suitable Materials

When used on the right materials, impact crushers offer significant benefits:

- Excellent Product Shape: Produces a highly cubic-shaped product.

- High Reduction Ratio: Can significantly reduce material size in a single pass.

- Cost-Effective for Non-Abrasive Rock: Lower operating cost per ton for materials like limestone.

- Ideal for Recycling: Superior performance in processing recycled concrete and asphalt.

Conclusion

In summary, an impact crusher is ideally suitable for crushing medium-hard, non-abrasive materials like limestone, recycled concrete, asphalt, coal, and gypsum. Its ability to produce a high-quality, cubicle product makes it a top choice for aggregate and recycling applications. However, for very hard and abrasive rocks like granite, a compression crusher like a jaw crusher or cone crusher is often a more durable and economical option. Always match the crusher type to your specific material for optimal results.

- > Construction Waste Mobile Impact Crusher for Recycled Aggregate Production

- > Which Crusher to Use for Manufactured Sand Production? A Complete Guide

- > Advantages of Using a 400×400 Roller-Type Stone Impact Crusher in Sand Production Lines

- > The Application of Cone Crushers in Iron Ore Crushing

- > Colombian-Made Mobile Impact Crusher

- > Utilizing Ball Mills for Limestone Crushing: Efficiency and Applications

- > Crusher Selection Guide: Choosing the Right Machine Based on Material Hardness

- > Optimized Ball Mill with a 50-Ton per Hour Capacity for Enhanced Ore Processing

Hot Product

Online

Message