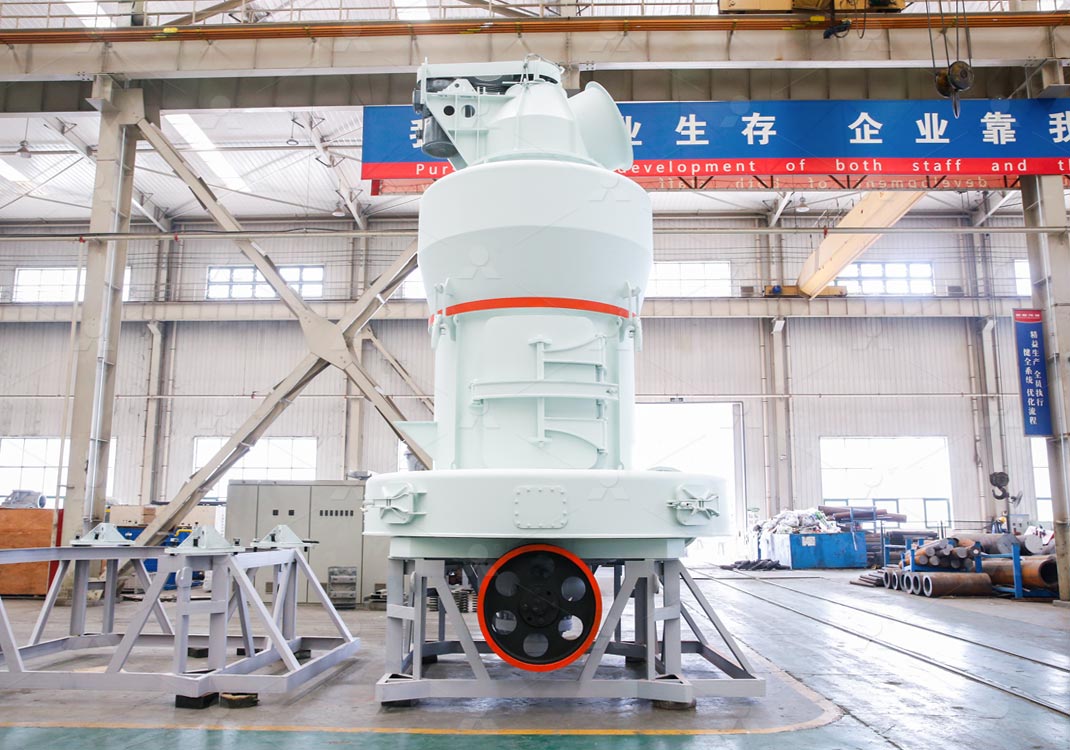

MTW-Z European Trapezium Mill

Overview

MTW Trapezium Mill has a large market share in the grinding industry. Whether it is bevel gear integral transmission, internal automatic thin oil lubrication system or arc-shaped air passage, these proprietary technologies make the machine advanced, humanized and green.

Applications:Feldspar, calcite, limestone, talc, barite, rare earth, marble, bauxite, phosphate ore, iron oxide red, dolomite, granite, bitumite, anthracite, lignite, kaolin, bentonite, gypsum.

Working Principles

The system consists of grinding mill, separator, air blower, jaw crusher, vibrating feeder, hopper, dust collector, pipe, powder collector, electric cabinet, motors, etc. Big lump materials are crushed to required size by jaw crusher, then elevated to buffering hopper through elevator, after that fed into the mill to be ground. Materials are to be ground between ring and rollers, and move up with the air flow, those particles which cannot pass the separator will fall down and be ground again, while others will be collected as finished product. Air flow passing through separator will go to the air blower for recycling, it’s a closed system.

Learn More About Liming® MTW-Z European Trapezium Mill

1.The power is strong and bevel gear drives overall. The transmission ratio is more accurate and transmission chain is reduced. Energy loss is reduced and efficiency is improved.

2.Both spindle drive system and fan transmission system adopt dilute oil lubrication, and the oil will be changed every 4 months. Oil exchange cycle is long and maintenance frequency is less.

3.New hanging type cage classifier makes output size adjustable and powder collecting efficiency improved.

4.The capacity reach up to 50t/h, which is superior to other grinding machines.

5.This machine has got many national patents with advantages of stable running and reliable performance. Besides, it has got environmental protection certification as industrial product. There is little duct and noise during grinding process, which can satisfy the requirements of national environmental protection.

Specifications – Technical Data

- > The Versatility of Cone Crushers: Material Processing Range and Applications

- > The Operational Characteristics of Cone Crushers

- > Efficient Copper Ore Processing with PF Impact Crusher

- > Mobile Crushers for Dolomite Crushing

- > How to Efficiently Crush High-Moisture Indonesian Coal with Impact Crushers

- > Challenges and Solutions of Using Impact Crushers for Crushing High-Moisture Clay in Indonesia

- > Granite Jaw Crusher with Durable Jaw Plates: Optimized for Long-Term Performance

- > Core Advantages of Mobile Impact Crushers in On-Site Rock Crushing

Hot Product

Online

Message